Why a Smooth Asphalt Surface Matters—and What Causes a Rough Finish

Over the years, we have seen thousands of driveways and parking lots installed, and one thing has always been clear: A well-done asphalt project stands out against one that was hasty and ill-considered. The quality of workmanship is evident to even a cursory inspection of the asphalt surface. An asphalt surface texture that appears uneven or lumpy is a tell-tale sign that the project was not given the care that it needed to be successful.

Attention to detail matters when it comes to asphalt. If the surface is not smooth, there was a misstep at some point in the process (whether it was a do-it-yourself project or one that was hastily performed by an unqualified contractor). In either case, bumpy asphalt is not simply an eyesore: it is a symptom of a greater issue.

Homeowners often think that a smooth asphalt surface is only a cosmetic issue. While it certainly looks better, more is at stake than curb appeal.

Why a Smooth Finish Is More Than Just Looks

Uneven asphalt causes small gaps and irregularities in the surface. When temperatures are mild, this may not be a big deal. However, in colder temperatures, those gaps allow water to penetrate. The water then freezes, and when it expands, it puts pressure on the asphalt from below.

When the ice melts, that pressure is relieved and the asphalt moves back to its original position. This freeze-and-thaw cycle repeats itself again and again. Over time, the asphalt weakens and eventually cracks.

It’s similar to what happens when you freeze and thaw a plastic water bottle repeatedly. The plastic becomes brittle and eventually breaks. Asphalt behaves the same way. The more stress it undergoes, the more susceptible it becomes to crumbling.

This process, over time, can lead to severe damage. Deep cracks, potholes, and depressions that collect water. That’s why having a smooth surface is critical to the long-term performance of your pavement.

What Causes a Rough Asphalt Finish?

- Too Little Asphalt to Bind the Aggregate

The application of asphalt should be smooth in texture. The consistency should be thick, soupy, and should adequately coat the aggregate material to hold the layer in place. As a minimum, asphalt should be 2-inches thick to ensure proper binding.

If not enough asphalt has been applied, the surface will not be bound together. Chips and small asphalt pieces will be found on the floor. This indicates that the aggregate material was not adequately covered or that it was not compacted.

Asphalt layer must sufficiently bind the underlying surface to ensure a long-term finish and prevent chipping and crumbling. This requires that a proper amount of material is applied in one layer and is rolled or tamped evenly for a smooth finish.

- Poor Compaction During Installation

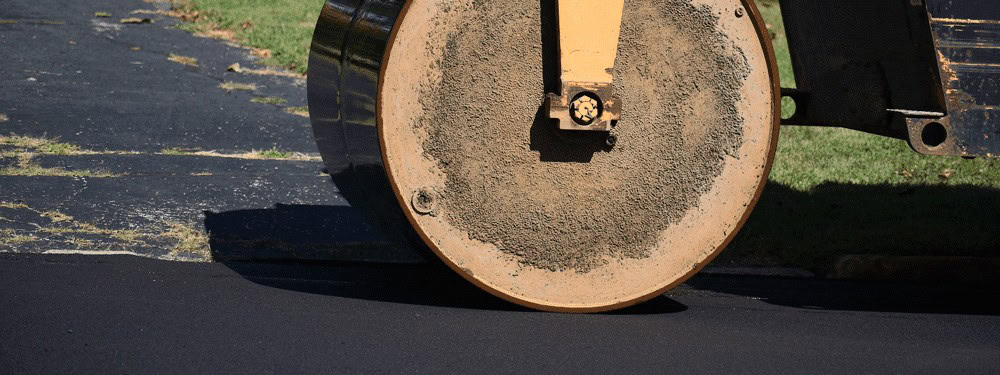

Another leading cause of rough asphalt pavement surfaces is a lack of compaction. After the asphalt layer is applied, it must be rolled or tamped to expel any air bubbles and gaps. If this is not done, the material will be loose, bumpy, and have soft spots that will not harden over time.

Compaction is a highly technical process. It eliminates all gaps and spaces and flattens out the floor for an even texture. Air bubbles must be removed before the asphalt cools and hardens. The work must be done correctly in a limited time window to achieve the correct density.

The process of compaction can only be done by an experienced contractor with specialized equipment to reach the necessary level of consistency. This is the only way to ensure that air pockets do not form and the surface does not separate over time.

- Improper Aggregate Mix

In addition, the base material under the asphalt coating has a major impact on the texture and consistency. A quality aggregate base material is made from a blend of larger crushed rock pieces and smaller compacted particles. This forms a tight, supportive base for the asphalt to bond to.

If the underlying material is mixed with smooth or round stones, they will not bind or compact tightly and evenly. This results in an unstable base layer with open spaces that weaken the pavement and prevent smooth application.

The best aggregate materials are made from angular and crushed rocks and pebbles to create a tight and even base layer. It will also help provide greater structural support for the asphalt, prevent shifting, and reduce damage over time.

Trust the Professionals for a Smooth, Long-Lasting Driveway

Is your asphalt looking a little rough around the edges? Cracking or wearing too soon? These are some of the signs of poorly installed asphalt. At Productive Asphalt, we pride ourselves in leaving our customers with high-quality asphalt surfaces, guaranteed to perform. Whether it’s your home driveway or a larger commercial paving project, we understand the proper processes needed to ensure the job is done correctly from the beginning.

Call on our professional team for asphalt installation, repair and maintenance services across New Jersey and Eastern Pennsylvania. Let us help you avoid common paving pitfalls and costly mistakes and enjoy a seamless finish that will last all year round and keep your property looking its best.

Get in touch today for a free estimate and ensure your next paving project goes smoothly!